The rapid evolution of industrial automation demands motors that are highly efficient, reliable, and capable of handling continuous operation. Among the innovations shaping this transformation, the stator hairpin motor stands out as a game-changer. Utilizing advanced hairpin stator technology, these motors offer superior performance, thermal management, and energy efficiency compared to traditional designs. As industries seek smarter and more sustainable solutions, stator hairpin motors are increasingly becoming the backbone of modern automated systems.

Understanding Stator Hairpin Motors

What Is a Stator Hairpin?

A stator hairpin refers to a stator design in which the motor windings are made from flat, rectangular wires bent into a hairpin shape. These hairpins are inserted into the stator slots and welded at their ends to form complete coils. Unlike conventional round-wire windings, hairpin stators allow for denser packing of copper, resulting in lower electrical resistance and higher efficiency.

How Hairpin Stator Technology Works

Hairpin stator technology improves the thermal and electrical performance of motors. The flat shape of the hairpins maximizes contact with the stator core, enhancing heat dissipation and reducing losses caused by resistance. This precise construction ensures motors can sustain higher loads while maintaining consistent performance, a crucial requirement for industrial automation.

Key Advantages of Stator Hairpin Motors

1. Enhanced Efficiency

Efficiency is a primary concern in industrial automation. Stator hairpin motors reduce electrical resistance and electromagnetic losses, translating to better energy conversion and lower operational costs. High efficiency also reduces heat generation, helping motors operate for longer periods without the risk of overheating.

2. Improved Thermal Management

Heat management is critical in motors running continuous or high-load operations. Hairpin stator technology allows for better thermal conduction and cooling due to the flat geometry of the windings. This advantage ensures stable performance, prevents overheating, and extends motor lifespan, which is particularly important in 24/7 industrial processes.

3. Higher Power Density

One of the significant benefits of stator hairpin motors is their ability to deliver higher power density. By packing more copper into the stator, these motors can produce greater torque and power without increasing their size. This compact yet powerful design is ideal for industrial automation systems where space constraints are common.

4. Increased Reliability and Durability

Industrial environments demand motors that are reliable and durable. The rigid construction of stator hairpin windings reduces the risk of vibration-induced wear and mechanical failure. Coupled with superior thermal performance, these motors offer a long operational life and minimal maintenance, making them highly suitable for automated production lines.

5. Reduced Electromagnetic Losses

Hairpin stator technology minimizes electromagnetic losses through precise winding geometry. This results in lower heat generation, higher efficiency, and consistent performance under high-speed or high-load conditions. Such characteristics are crucial for motors used in precision industrial machinery and robotics.

Applications in Industrial Automation

Robotics and Automated Machinery

Robotics relies heavily on precision, efficiency, and reliability. Stator hairpin motors provide smooth and accurate motion, even under continuous operation. Their thermal management capabilities ensure that robotic systems can operate for extended periods without performance degradation.

Conveyor Systems

Conveyor systems in manufacturing and packaging industries operate non-stop and require consistent power. Stator hairpin motors improve efficiency, reduce energy consumption, and minimize downtime, ensuring smooth operation of conveyors and material handling systems.

CNC Machines and Precision Tools

Computer Numerical Control (CNC) machines demand high torque, precision, and stability. The compact yet powerful design of stator hairpin motors allows these machines to perform intricate tasks efficiently, enhancing product quality and reducing production errors.

Packaging and Material Handling Equipment

High-speed packaging and material handling lines benefit from the durability and energy efficiency of stator hairpin motors. The enhanced power density and thermal management allow these motors to operate reliably under continuous, high-demand workloads.

Renewable Energy-Integrated Automation

Some automated industrial systems integrate renewable energy sources such as solar or wind. Stator hairpin motors can adapt to variable energy inputs efficiently, ensuring stable performance and supporting sustainable industrial practices.

Manufacturing and Design Benefits

Streamlined Production

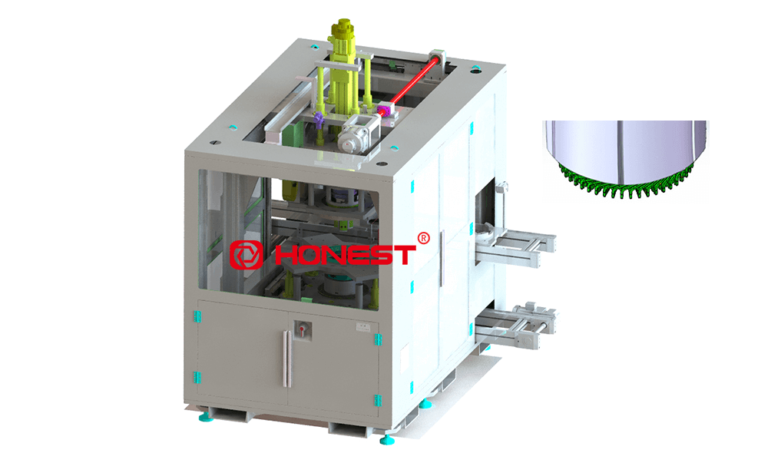

Hairpin stator technology allows for automated manufacturing processes that insert and weld hairpin windings with precision. This reduces manual labor, enhances consistency, and ensures scalable production of high-performance motors for industrial automation.

Design Flexibility

Engineers can leverage stator hairpin technology to optimize motor design for specific industrial applications. Whether prioritizing high torque, compact size, or maximum efficiency, hairpin stators offer flexibility unmatched by traditional winding methods.

Future of Stator Hairpin Motors in Automation

As industrial automation evolves, the demand for efficient, reliable, and compact motors will continue to grow. Hairpin stator technology is positioned to meet these requirements, driving innovation across robotics, manufacturing, packaging, and energy-efficient automation systems. Continued advancements in materials and production techniques will further enhance performance, solidifying stator hairpin motors as the future of industrial automation.

Conclusion

The adoption of stator hairpin motors marks a significant shift in industrial automation. Leveraging hairpin stator technology, these motors deliver higher efficiency, better thermal management, increased power density, and unmatched reliability. From robotics to conveyor systems, CNC machines, and renewable energy-integrated operations, stator hairpin motors are redefining performance standards. As industries strive for smarter, more efficient automation solutions, stator hairpin motors are undeniably the driving force shaping the future of industrial automation.